THE A-FRAME

Francesco Pelizza - Founder & Director of AMS

AMS developed - in conjunction with CDM’s Technical Department - the project of the A-frame crane featured on the Flexplorer Aurelia recently launched by the yard. CDM met Francesco Pelizza, founder of AMS, to better understand this peculiar crane.

Francesco, you have a long experience in designing structures for both the aeronautic and yacht industry, would you please tell us what are your working methods and your approach to designing complex mechanical parts to be installed on large yachts. We can summarize our approach to each project with three key words/concepts: responsibility, sharing ideas, quality. I founded AMS in 2005 and since its inception we designed and produced hundreds of bespoke products and mechanical parts for the yachting industry from telescopic light masts in pre preg epoxy carbon fibre to poles and awnings with mechanical tension systems, from hull and garage doors and hatches to foldable balconies and bulwarks to transom doors. AMS, trough the most advanced carbon fibre lamination technologies, is able to manufacture items with very complex shapes that could not otherwise be produced using conventional materials. All projects are developed in conjunction with our clients to whom we offer custom and state-of-the-art solutions. We also offer an array of engineering services such as scantlings, Finite Elements Analysis, Structural Design, 3D and 2D design and project management.

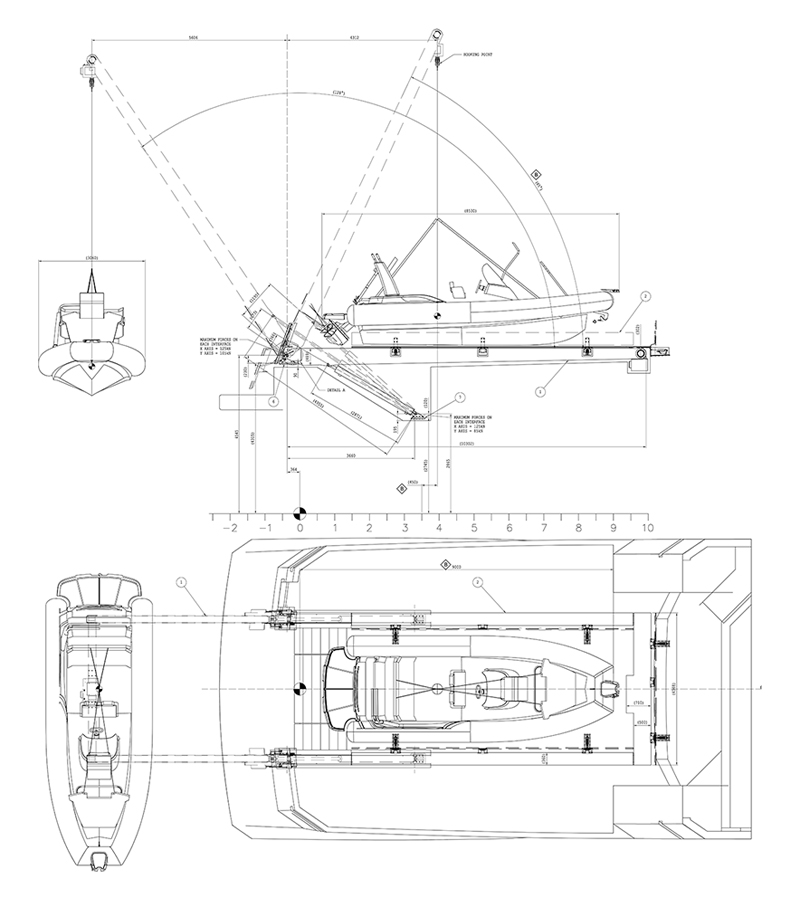

AMS designs and produces cranes, too, and the A-frame installed on the Flexplorer Aurelia is a very peculiar one. What are its main characteristics? Throughout the years we have produced a lot of cranes and tender launching systems tailored according to the space available on board, the lifting capacity required and the handling needs of the vessel, yet I have to say that the A-frame crane represented a first and a true challenge. With the A-frame crane, Ennio Cecchini and the CDM’s team really had a stroke of genius! We embraced the idea with enthusiasm and worked with the CDM team shoulder to shoulder to bring the project to completion. A-frame cranes are usually designed to perform offshore load handling on ships, fishing and research vessels, Aurelia’s A-frame crane is the first crane of this kind ever used on a luxury yacht. Cranes are usually considered a nuisance as they ‘steal’ space and are not so nice under the aesthetic point of view. On top of that, when you deal with launching and hauling a heavy tender there are heeling issues as the weight force acts just on one side of the yacht. With the A-frame crane the tender is launched or hauled right astern and the yacht doesn’t heel at all. Furthermore, working behind the stern offers a shelter which allows operating in smooth waters. ‘Our’ A-frame crane is a highly sophisticated piece of engineering built entirely in carbon fibre to be as light and stiff as possible. It is composed by two pillars and a transverse cylindrical element that encompass and holds the winch that has to be free to rotate to remain always in perpendicular position (that is aligned with the gravity force) while the frame rotates. The main dimensions of the frame are (B x H) 4.2m x 10.1m, the structural carbon weight is 460kg and the total weight is 1150kg. The lifting capacity is above 3 tons. The two pillars have been laminated in two pieces each and then bonded together, and secondary bonded with the top transverse cylindrical element. The whole structure, when not in use, is recessed into the deck floor and hidden underneath flush deck flaps. We designed the automatically-operated flaps, too. The A-frame crane must operate smoothly in all positions and the structure, while moving from ‘rest’ position to launching position undergoes critical stresses. The first critical position occurs when the structure starts rising from the deck and, due to the very narrow angle, the weight force on the actuators is at its maximum. Moreover, the actuators must work in perfect synchrony to make the structure operate without any torsion or misalignment. Another critical position is reached when the structure reaches an obtuse angle to let the tender hang beyond the stern to be launched or hauled.

What about your relationship with CDM? We’ve been working with CDM for many years on a great number of projects. We have built stern doors, hatches, handling systems, cranes, foldable bulwarks for CDM explorer yachts of the Darwin Class, Nauta Air and Acciaio series and for custom projects such as Audace and Crowbridge. We are developing a new, larger A-frame crane for the Flexplorer 146. Our relationship with CDM is excellent under all aspects and when we work on a project we join forces and really become an unique team.